Everything you need for Waste management in a Smart City

Smart Waste

WGW's smart waste management solution empowers cities to manage and battle ever-growing volumes of urban and municipal waste. The growing volumes of waste are largely caused by two factors: large-scale urbanization and industry growth. The modern lifestyle around the globe produces much more waste per citizen than only a decade ago. The United Nations projects 66% of the world´s population will live in cities by 2050. To sustain all these factors, problems and challenges, cities need a sophisticated and efficient tool to manage waste, monitor bins with sensors, and optimize capacity and collection routes.

WGW's solution can help cities be smarter with waste

- Understand production of waste in your city

- Improvement of the environment in your city

- Provide citizens with more efficient waste management

- Evaluate the bin infrastructure in the city in terms of density, efficiency and cost

- Optimize waste bin capacity, location, and type

- Optimize waste collection frequencies, reduction of costs

- Be able to collect waste on demand, reflecting the actual need

- Relieve traffic congestion in city related to regular waste collection routes

- Provide citizens with free mobile app enabling to find nearest available empty bin, directions and single click notification to the operators

Smart combination of hardware and software

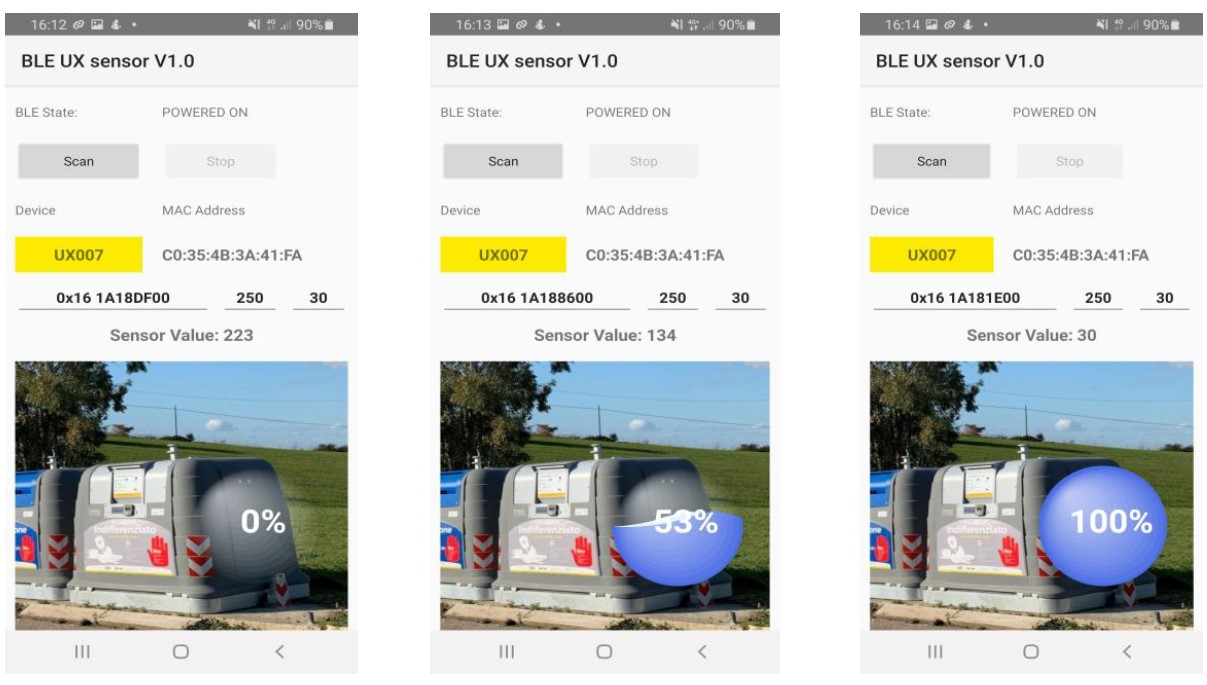

WGW's smart waste management technology uses a variety of Smart Sensors ,open APIs, advanced analytics, and leveraging mesh-network topology. It's this unique combination that provides the intelligence of the solution so that it is easily customizable for any network (etc. NB-IoT, LoRaWAN, GPRS) and through real-time data monitoring and analyses, provides better information that helps to avoid collecting empty or half-empty waste bins.

Improve the well-being of people

Cities can improve the well-being of citizens with the smart waste management solution by WGW. The implementation of our solution helps to optimize the capacity of bins and to promote separation of recyclables by residents. With sufficient capacity, there is always enough space for people's trash - general and separable. The need-driven waste collection eliminates unnecessary traffic blockage and overflowing bins. Cities, as a result, become cleaner and free of litter, trash and garbage and sustainable solutions like recycling are promoted.

Engage people via smart mobile app

Activate people via WGW's BrainWaste App. The mobile application informs people of the nearest available empty bin, helps them find the right bin for their waste type - general, glass, plastic, etc., and enables them to be more environmentally responsible. By providing real-time feedback via the mobile app, citizens can help reduce overflowing and messy bins.

Improve the environment

Well-managed waste in the city with WGW's smart waste management solution improves the environment. The real-time data monitoring, Smart Analytics, and Smart Route Planning ensure more efficient waste collection, resulting in fewer cars, less noise, less traffic, and a carbon emission reduction of up to 60% in cities and most of all - a litter-free city. Additionally, the sensors are equipped with replaceable batteries and are made from recyclable polyimide optical fibers that provide not only an eco-design, but also help with recycling.

Electronic device for the control and management of waste containers through user identification, recognition of areas and types of material, opening control, data transmission

Makes possible to implement computerised waste disposal in traditional roadside containers and any other waste disposal point (bins, bells, underground islands, eco-centres), without changing citizens' habits or the organisation of the service.

- Updates charging by parametrising it to the quantity of waste produced

- It uses the technology of the Kupolina volumetric limiter, with all technical and functional features relating to computerised access control, remote programmability and management of data relating to deliveries and emptying.

- It is available in different versions to suit different types of containers and can be integrated with a volumetric sensor for real-time control of service efficiency.

The electronic card makes it possible to trace all the stages of the "waste chain", detecting

user side

- user identification tag code

- bin identification data

- date and time of waste disposal

- progressive delivery rate

- functional parameters of the system

vehicle side

- bin identification data

- date and time of emptying

- system functional parameters

The main features of the system are:

- access control of users who, by using a card (tag) with contactless RFID technology, identify themselves when opening containers or accessing collection centres

- user authorisation: the user is identified by means of a tag or APP and is enabled to deliver waste according to the logic (white/black list, zone, material) provided by the SA

- container identification: each container is identified by a master file containing a unique id and all its characteristics: volume, type of waste, geographical coordinates, photo

- geographic position acquisition: each device is equipped with a GPS-based automatic

position detection system, capable of autonomously acquiring geographic coordinates to

identify the location of the container in the area - transmission of delivery data to central systems: the devices transmit delivery data to the

customer's central system using the MQTTS protocol - acquisition and storage of blacklists/whitelists: the devices receive and store lists of users

to whom access is permitted or inhibited - access authorisation: there are two access control modes, which can be activated by

command from the loT platform: - authorisation based on a code (e.g. zoning) pre-coded on the tag with the possibility of

modifying the codes accepted by each device via remote programming (blacklist/whitelist) - authorisation based on a list of enabled tags (whitelist), to manage particular types of waste

(such as nappies).

Smart press container KOMP@CT-P

KOMP@CT-P is not a simple compacting sliding container. It is an Innovation for Waste Separation, which evolves conventional systems to meet both user and service needs.

European and national legislation on waste management becomes more complete and precise every day, overwhelmed by environmental and energy policies. Non-recyclable waste must decrease and citizens have to be subsidize to recycle through a charging based on actual waste production. Hence, there is a need for constant monitoring of the contributions and reorganization of the resources used in the collection.

The solution is Komp@ct-P, the equipment that allows you to enable, weigh, and record a large amount of contributions, allowing for timely handling of the tariff and, on the other hand, reducing the emptying services.

All this gives

the citizen the opportunity to deposit waste at any time without being

obliged to split and accumulate the various fractions in the house,

pending the day of withdrawal.

Combining these three factors,

comfort, traceability and long autonomy is a winning card that results

in actual savings in the collection. Suffice it to think that a 15 m³ compactor can serve 300-400 families for a period of 40 days.

Like all WGW's equipment, Komp@ct-P is equipped with a sophisticated computer system, which acts as a user interface and remote control for the service manager. In addition to the many standard features, there are many customizations of operation and management to meet all your job requirements

Onboard Devices

An on-board computer with touchscreen, in compliance with the EU laws regarding the

CE marking. It allows the management of the identification and weighing of

waste bins as well as their location, the management of the waste truck

itinerary, the registration and transmission of data for operating parameters

and service with compact flash via GSM / GPRS (through fixed ftp connections).

Waste bin identification

The RF-id unit reads the transponder on the container and registers the data of the emptying operation in definite and ambiguous way.The antennas, situated on the container lifting mechanism, are made of bump resistant material and protected by a metal shell, have a range of 200 mm with automatic calibration and operate in series on 4 independent channels to allow simultaneous identification of multiple bins, in order to reduce the time and the emptying cycles. The transponders installed with the system have an operating frequency of 125 KHz, a wavelength authorized by the Communications Ministry.

Weighing

The onboard computer can be integrated with a homologated electronic weighing system. Weighing is carried out with load cells and can be done in static or dynamic mode, depending on the applications and work requirements.

Dynamic weighing does not create slowdowns or limitations to the drain cycle of the bins

and is able to detect the data in any condition of use and with any type of

"lift", automatically determining the tare in the positioning stage.

The weighing is associated with the container transponder code along with other

collection information (vehicle code, date, time, progressive, position

coordinates) stored in a progressive record both on internal memory and on

compact flash back up and transmitted via radio , Wi-Fi or GSM / GPRS to the

receiving base station (any data platform). The weighing with

back side or lateral side trailer hydraulic tipping is an example of dynamic

weighing.

Static weighing is made through load cells placed on the chassis of the vehicle (sub-box) and is useful for measuring large masses, not allowing adequate precision for small quantities. The device, suitably dimensioned according to the maximum load, returns certified minimum weights in Class III and Class IV.

Examples of static weighing:

- Weighing for dumpster truck

- Weighing under the cargo

- Weighing for tanks

- Weighing for silos